Spring Energized Lip Seals

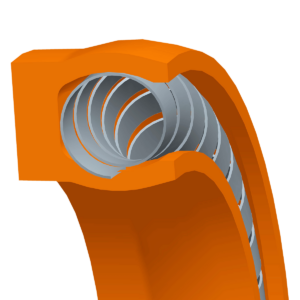

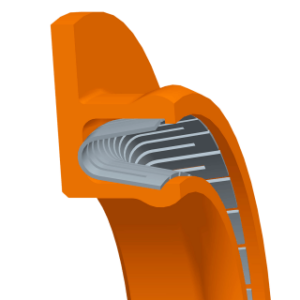

The Eurosealings spring-energized PTFE seal represents the latest generation of spring-activated Teflon seals. These seals feature a specialized precision jacket/lip crafted from Teflon (or other high-performance polymers) and a corrosion-resistant stainless steel spring.

This unique combination allows the spring to press the seal lips against the gland and rod walls, with the pressure further assisting the spring force. The spring adjusts for lip wear, hardware tolerances, and eccentricities, providing continuous resilience to the seal lips. The Eurosealings design, with its sealing lip and spring arrangement, offers superior leakage protection compared to traditional lip seals.

Benefits

- Temperature -250°C to +300°C

- Chemical resistance against almost all medias

- Low friction coefficient

- No stick-slip-effect

- Diameter range from 2 mm to 3000 mm

Radial Seals

Apart from the standard shapes listed below, we develop variants customized to the respective application.

Our technical department will be pleased to advise you.

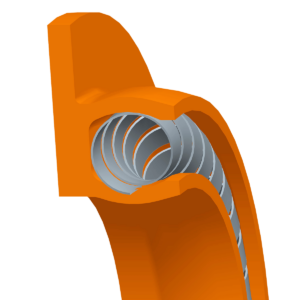

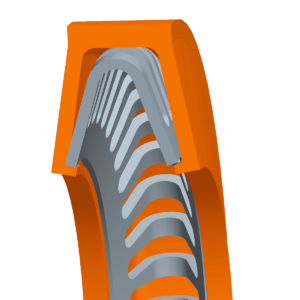

Standard Type

Standard type with inserted coil spring

Type 103

The standard type of seal features an inserted coil spring and a symmetrical design with rounded sealing lips. Thanks to its high spring forces, it is well-suited for static or mildly dynamic applications.

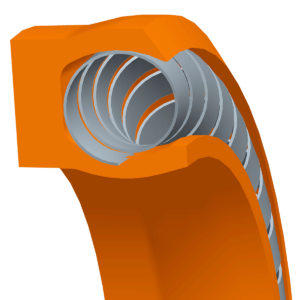

Type 113

Same as type 103, but equipped with a sharp scraper edge on the inner diameter, it is ideal for use as a rod seal in fluid translational movements. Its design offers high spring forces, making it well-suited for such applications.

Type 123

The standard type of PTFE seal, combined with a sharp scraper edge on the outer diameter, is particularly suited for use as a piston seal in fluid translational movements. Its high spring forces and scraper edge make it well-suited for this application.

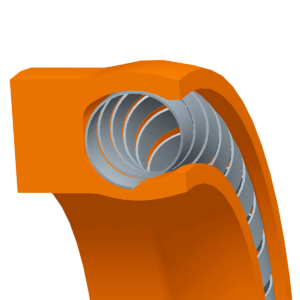

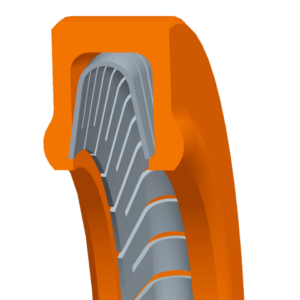

Type 103H

This seal is featuring a reinforced back and is specifically designed to withstand high pressures. It’s robust construction and high spring forces make it well-suited for applications requiring pressure resistance.

Type 143

The standard type of PTFE seal, equipped with a retaining flange as an anti-rotation device, is particularly designed to prevent the seal from rotating in rotary applications. Its inclusion of a retaining flange ensures stability and makes it well-suited for such applications.

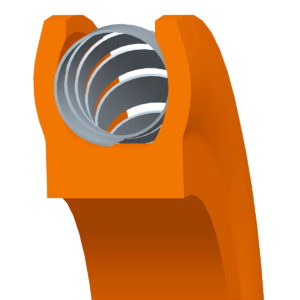

Special

The encapsulated version of the standard PTFE seal features a coiled spring that is fully encapsulated, resulting in a dead space-free sealing solution. This design is particularly suitable for butterfly valve seals, with its compliance with FDA regulations, making it ideal for applications in the food industry.

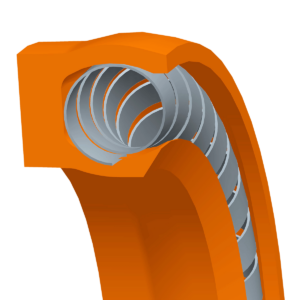

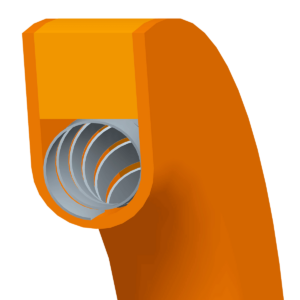

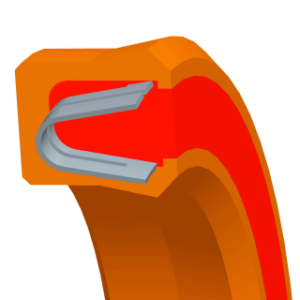

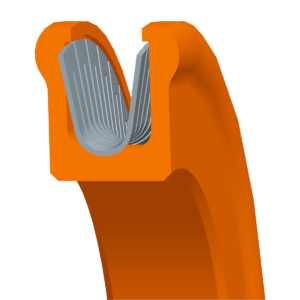

V-Spring Type

Standard type with inserted coil spring

Type 400

The V-shaped spring-energized PTFE seal, with an inserted V-spring and symmetrical design featuring rounded sealing lips, is well-suited for dynamic applications. Its sealing lips offer high flexibility, while the low friction properties ensure smooth operation.

Type 401

This seal features a sharp scraper edge on the inner diameter. This configuration makes it ideal for use as a rod seal in translational fluid movement applications. Combining the V-shaped spring, sealing lips’ flexibility, and scraper edge enhances its performance and effectiveness.

402

Standard 400 V-type, enhanced with a sharp scraper edge on the outer diameter. This configuration makes it well-suited for a piston seal in translational fluid movement applications. The V-shaped spring provides flexibility to accommodate dynamic movements, while the scraper edge helps maintain effective sealing and prevent contaminants from entering the system.

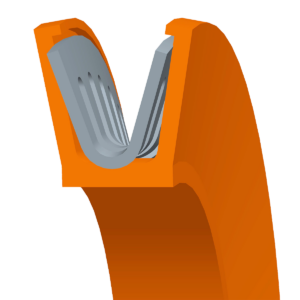

Type 4VS

This seal has a symmetrical design with chamfered sealing lips on both sides. This design allows for precise and controlled fluid dispensing, making it well-suited for applications that require accurate dosing or metering. The symmetrical construction and chamfered lips ensure efficient sealing performance and minimal fluid leakage.

Type 414

The standard V-shaped spring-energized PTFE seal, equipped with a retaining flange as an anti-rotation device, particularly suitable for rotary applications. The retaining flange ensures the seal remains in place and prevents unwanted rotation during operation.

Type 4FM

The standard V-shaped spring-energized PTFE seal, but further enhanced with an encapsulated spring chamber using an FDA-approved silicone sealing compound.

This design ensures low dead space, reducing the areas or gaps where residues can accumulate or become trapped. The encapsulation eliminates potential areas for product buildup or contamination, maintaining hygiene standards. Its compliance with FDA regulations and the use of a reliable sealing compound make it an excellent choice for food-related applications.

Axial Seals

Apart from the standard shapes listed below, we develop variants customized to the respective application.

Our technical department will be pleased to advise you.

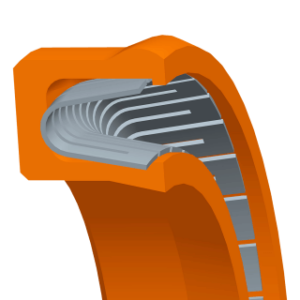

For Internal Pressure

Type 403

A PTFE seal featuring a symmetrical design with rounded sealing lips, suitable for both dynamic and static applications, incorporates an inserted V-spring.

Type 304

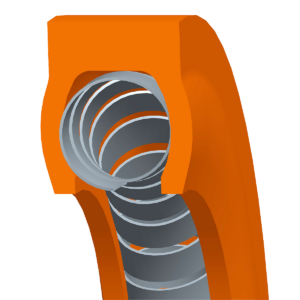

A symmetrical PTFE seal with rounded sealing lips, designed for dynamic and static applications, achieves high pressing force through an inserted coiled spring.

Type 1100

Designed for static to slowly dynamic applications like swivel joints, this seal offers high pressing force and a large pressing stroke, equipped with a full contact spring.

Encapsulated Type

This seal is customized for static to slowly dynamic applications, such as swivel joints, and features high pressing force and a long pressing stroke, enhanced by an inserted steel ring for increased stability.

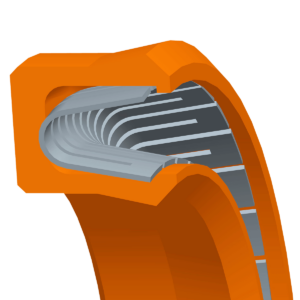

For External Pressure/Vacuum

Type 404

A symmetrical PTFE seal, designed with rounded sealing lips for both dynamic and static applications, features an inserted V-spring for enhanced performance.

Type 314

A symmetrical PTFE seal, designed with rounded sealing lips for both dynamic and static applications, features an inserted V-spring for enhanced performance.

Type 1101

Designed for static to slow dynamic applications like swivel joints, this seal offers high pressing force and a large pressing stroke, complemented by a full contact spring.

PTFE Seal Jacket Materials

Over 250 compounds are available for the material of the seal jacket, catering to diverse application needs.

The table below highlights a range of available options. Furthermore, custom compounds tailored to specific application requirements are also available upon request.

| Material Description | Relative Wear Resistance 1=low, 9=high | Temperature Range Degrees [°C] |

|---|---|---|

| PTFE-virgin Recommended for low to moderate dynamic or static service. Low gas permeability. FDA approved. Good cryogenic (low temperature) properties. | 3 | -250 ... +205°C |

| PTFE-virgin modified Recommended for low to moderate dynamic or static service. Lowest gas permeability. FDA approved. Higher creep resistance, very high chemical resistance. | 3 | -250 ... +215°C |

| PTFE-reinforced with Carbon and Graphite Excellent universal properties for higher temperatures and resistance to wear. Especially suitable for hot water, steam service, and poor lubrication. | 8 | -130 ... +290°C |

| PTFE-filled with Graphite Excellent general-purpose material with low friction, good wear, and heat resistance. Non-abrasive. Suitable for water service, dry or poorly lubricated applications. | 7 | -130 ... +290°C |

| PTFE- filled with Glass fiber and MoS2 Extremely abrasion resistant, recommended for high-pressure hydraulic, water, and steam service. Abrasive wear may be possible at high speeds and with soft metal surfaces. | 9 | -155 ... +290°C |

| PTFE-reinforced with special filler Superior wear and heat resistance. It may also be used for soft metals. No abrasive wear. Recommended for static and dynamic service, high temperatures, and high speeds. | 8 | -155 ... +316°C |

| UHMW-PE modified Excellent wear-resistant, but limited chemical and heat resistance. Especially suitable for abrasive media and water-based liquids. FDA approved. | 9 | -240 ... +104°C |

PTFE Seal Operation Range

The extensive range of options ensures that all radial seals' sealing requirements can be met. It's important to note that not all maximum stresses can be simultaneously applied to the seal.

With a variety of designs, jacket and spring materials, and different dimensions, these seals can be used in a wide range of working conditions, including:

- Temperature range from -250°C to +316°C

- Suitable for rotation and reciprocating movements up to 5 m/s

- Static applications with pressures up to 3500 bar

- Dynamic applications with pressures up to 550 bar

- Universally resistant to chemicals

- Applicable for vacuum and ultra-high vacuum (UHV) applications

- Available in diameters ranging from 2 mm to 3000 mm.

Spring Energizer Preload Elements

The selection of preload element materials for coil and V-shaped springs, such as SS301 (standard), Elgiloy, Inconel, and Hastelloy, is crucial in achieving optimal performance and reliability.

| Coil Spring | V-Shaped Radial Spring | Material Code | |

|---|---|---|---|

| 301 Stainless Steel (Standard) | x | x | 1.4310 |

| Elgiloy | x | on request | 2.4711 |

| Inconel | x | 2.4669 | |

| Hastelloy | x | on request | 2.4602 |

| For other Stainless Steels, such as 316, 302, 17-7PH, ask our Technical Service | |||

Let us help you

PTFE seals offer a wide range of possibilities to address various sealing challenges. However, it is essential to recognize that every situation is unique, and selecting the proper seal and coating is crucial to avoid potential issues and ensure cost-effectiveness in the long run.

We invite you to contact our team to find the optimal sealing solution for your specific application. Our experienced professionals are ready to assist you in identifying and specifying the correct seal and coating tailored to your unique requirements.

Avoid Pitfalls in PTFE Sealing Design

Let us help you tailor your unique sealing solution. Every project is unique, and we've seen many mistakes that could have been avoided.

Contact us today to create a seamless sealing solution with PTFE seals from Eurosealings.