Laser- & Sensor Technology

Our spring-energized lip seals and resilient metal seals are renowned in the laser industry for their exceptionally low leakage rates.

We provide highly effective sealing solutions for a variety of applications, including optical measuring devices, CO2 laser cutting heads, and ultrashort pulse lasers, among others.

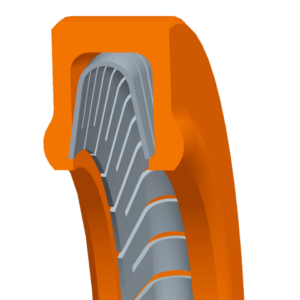

PTFE Dust Seal

A laser cutting machine produces a high-powered laser beam that cuts through materials with exceptional accuracy. The laser head glides and rotates over the material to carve out a desired pattern.

During the cutting process, fine particles from the material scatter around the cutting area. Moreover, dust from other manufacturing processes can accumulate in a workshop.

Laser-cutting machines have an internal dust seal that’s designed to protect the internal mechanisms from infiltration by dirt and dust.

Any friction can cause potential distortions in the movement of the laser head, resulting in inaccuracies in the cut. Therefore, the dust seal is a PTFE lip seal with extremely low friction. PTFE has one of the lowest coefficients of friction of any solid material. It’s also a highly wear-resistant material, which ensures durability and low maintenance.

The dust seal is typically enclosed in a removable cassette and needs to operate under very low pressure. To guarantee a reliable springback under low pressure, the PTFE seal is spring-energized.

Although temperatures at the cutting point can be extremely high, the operating temperatures surrounding the dust seals only get up to 70°C, which is well in the temperature range of PTFE.

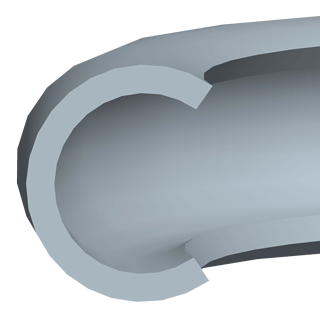

Housing Seal

The housing of the laser head is engineered to protect sensitive optical components, maintain precise alignment, and manage thermal conditions to ensure consistent, high-precision laser cutting while also being durable and accessible for maintenance.

The housing seal is a metal C-ring, used to achieve and maintain the defined pressure ratios over long periods of time.

This C-ring is vital for safeguarding the laser’s internal components from contamination and is designed to achieve minimal leakage rates, even under low-pressing conditions.